From Wired to Battery: A New Phase in Track & Trace

What you need to know about the transition to battery-powered systems

Track & Trace solutions have been a staple in logistics, construction, and asset management for many years. Until now, wired systems were the standard: stable, reliable, and directly connected to a fixed power source. However, in more and more situations, this proves to be insufficient.

Why battery-powered trackers are on the rise

Battery trackers make it possible to track assets that do not have a fixed power source: containers, trailers, agricultural machinery, or loose tools. This flexibility allows companies to gain more control over their entire operation – not just on vehicles or machines that are already wired.

The technology has undergone significant development in recent years. While many early models disappointed due to short battery life or limited robustness, we now see a generation of devices that actually deliver on their promises in practice.

What to look for in battery trackers

Choosing a battery-powered tracker sounds simple, but there are many factors to consider. For example:

- Battery life: is strongly influenced by settings and usage patterns.

- Size: if you have more space, opt for a larger tracker; it can hold more batteries and can last up to 15+ years (depending on the settings).

- Environmental factors: outdoor use requires a more robust housing than indoor tracking.

- Connectivity: do you choose LTE-M/NB-IoT, LoRaWAN, or go with 2G fallback; coverage varies by region.

- Usability: easy installation and management makes scaling much easier.

It is therefore important to not only look at the specifications on paper but also at the performance in practice.

Smart management of battery life

The battery life of a tracker strongly depends on the settings. How often should a location update occur? Are you using GNSS, WiFi sniffing, cell-ID, or all three? And how do you handle stationary or moving situations?

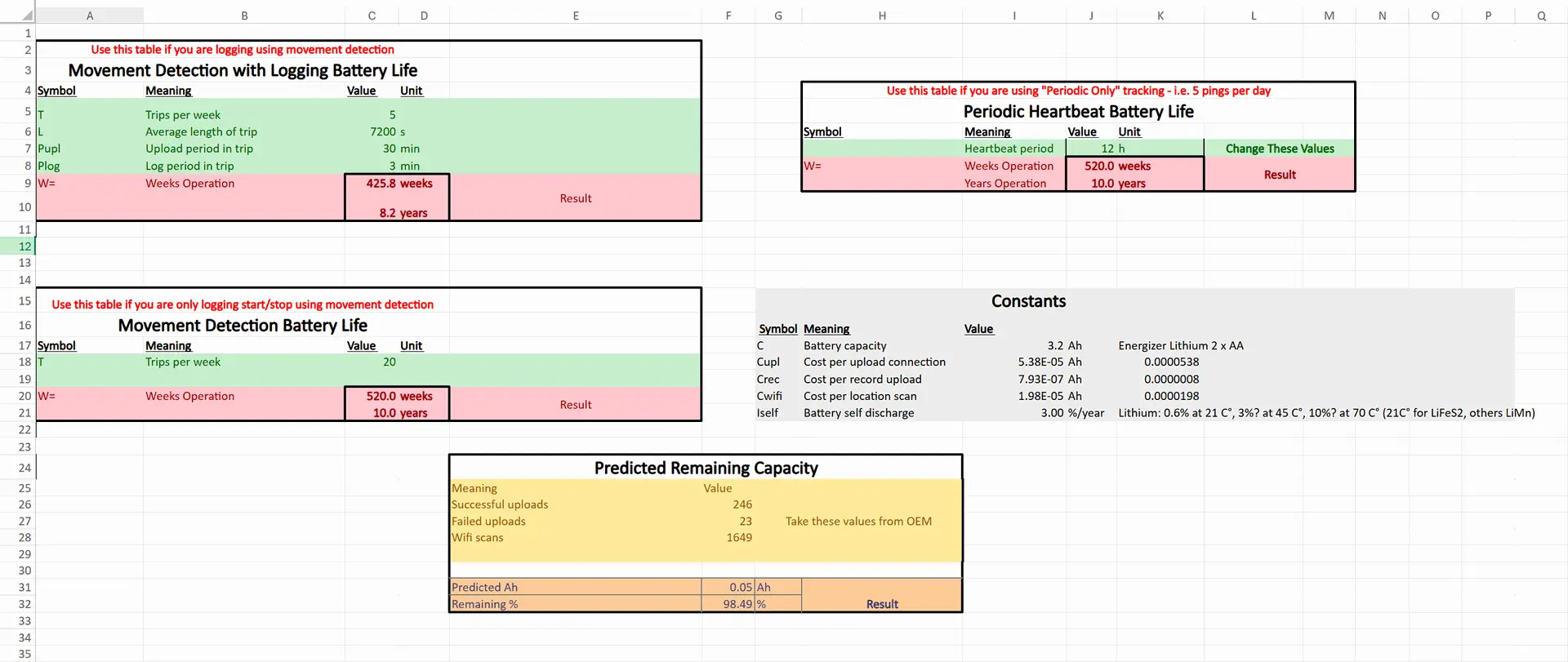

Many people find this difficult to estimate, but there are handy calculation tools available that allow us to work through the settings. This way, you immediately gain insight into how long a tracker can last – often this amounts to many years.

💡 Example: a tracker that reports a position every 12 hours can last over 8 years on a single battery. If you shift that to every 10 minutes, the lifespan decreases significantly. With the right settings, you can find the balance between detail and lifespan.

More data is not always better

It may sound logical: the more often a tracker reports, the better. But that's often not necessary. If an asset is stationary, you already know where it is – it adds nothing if you receive the same coordinates every 10 minutes.

With a built-in accelerometer (motion sensor), you can solve this smartly. The tracker only transmits a new position when there is movement, and as soon as the object comes to a stop, it automatically sends the last location. This way, you get the relevant data without unnecessarily draining the battery.

Miggy as an intermediary

For many companies that already offer track & trace, it doesn't make sense to reinvent the wheel. They often already have their own portal or work with an existing software solution. Nevertheless, their customers are increasingly wanting to use battery-powered trackers.

That's exactly where Miggy comes into play. We are the link between the hardware and your existing services.

-

Your customers remain your customers – you always maintain control and customer contact. We provide support and technology in the background, so you can maintain and strengthen your relationship with the customer.

- Flexible access – you decide how much access you want to the back-end. Do you want to manage everything, or just the essentials? Both are possible.

- Data integration – through the device manager, we send data directly to your own application server or portal. This way, you keep everything centralized in your existing environment.

- Freedom of choice – you can purchase the complete solution from us, or just the parts you need. Because we buy in bulk, you always benefit from favorable rates.

In this way, we make battery trackers accessible for companies that want to enhance their own systems without compromising their existing way of working.

Prefer a complete solution without technical integration?

Miggy can also provide the entire solution as a white-label service. This way, you present a complete service under your own name, while we take care of the technology and support in the background.

Conclusion

The transition from wired to battery-powered trackers opens up new possibilities for tracking assets, from containers and trailers to loose machinery and tools. Successful use depends not only on the hardware but especially on smart settings and thoughtful integration into existing systems.

By making conscious choices about reporting frequency, use of sensors, and data processing, you maximize the technology and ensure the battery remains reliable for many years.

Whether you take control yourself with an integration via Miggy or opt for a complete white-label solution, there are plenty of opportunities to expand your track & trace services without compromising your existing customers and systems.

💡 Do you want to see how battery trackers work in practice? Feel free to request a demo and experience what is possible for yourself.